Necessary Guide to Undercarriage Parts for Heavy Devices

When it comes to hefty devices, the undercarriage plays a critical function in ensuring reliable and smooth operations. From track chains to rollers and idlers, each element contributes to the total capability of the tools.

Significance of Undercarriage Parts

Recognizing the essential function that undercarriage parts play in the efficiency and long life of heavy tools is paramount for reliable upkeep and operation - undercarriage parts. The undercarriage parts create the foundation on which the whole maker runs, supporting the weight of the tools, providing stability, and soaking up shock lots throughout procedure. A well-maintained undercarriage not only makes certain smooth procedure yet also contributes significantly to minimizing downtime and repair work prices

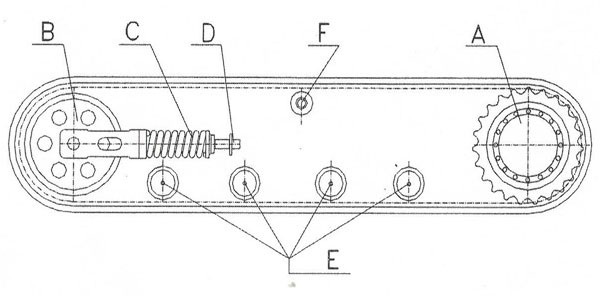

The undercarriage is composed of various vital parts such as track chains, track footwear, sprockets, idlers, rollers, and track frameworks. Each of these parts plays an essential function in the overall performance of the tools. The track chains and track footwear aid in offering grip and assistance, while the idlers and gears aid in driving the tracks smoothly. Normal assessment, timely upkeep, and replacement of damaged undercarriage parts are vital to avoid break downs and maximize the life-span of the heavy tools. Basically, purchasing high-quality undercarriage components and ensuring their correct care is essential for ideal performance and toughness of hefty machinery.

Types of Track Chains

Track chains are vital elements of hefty equipment undercarriages, supplying the essential grip and support for efficient operation. There are primarily 2 kinds of track chains used in heavy devices: sealed and lubed track chains (SALT) and completely dry track chains.

Function of Rollers and Idlers

Rollers and idlers play a crucial function in supporting and directing the track chains of heavy equipment undercarriages, contributing to the overall security and performance of the machinery. Idlers, on the various other hand, overview the track chain and aid keep correct tension throughout the undercarriage system.

With each other, rollers and idlers function in consistency to make certain that the track chain remains in location, even on harsh terrain, boosting the equipment's performance and durability. Appropriate upkeep and normal assessment of idlers and rollers are vital to avoid premature wear and prospective break downs, inevitably maximizing the check that effectiveness and lifespan of heavy devices undercarriages.

Comprehending Gears

One critical facet of gears is making certain appropriate placement and stress to stop premature wear and damage. Misaligned gears can trigger irregular wear on the track chain, bring about reduced efficiency and potential safety and security dangers. Regular upkeep and evaluation of sprockets are important to recognize any kind of indications of wear or imbalance promptly.

In addition, sprockets can be found in different sizes and tooth setups, depending upon the details heavy devices and its intended use. Correct choice of gears based upon the tools's requirements is important to ensure optimum performance and long life of the undercarriage system. Comprehending the function of sprockets and their maintenance requirements is important for making the most of the efficiency and lifespan of hefty devices undercarriages.

Upkeep Tips for Long Life

To guarantee the prolonged durability and ideal functionality of hefty equipment undercarriages, thorough upkeep techniques are crucial. Routinely examining undercarriage parts such as track footwear, rollers, idlers, and Read Full Article sprockets for wear and tear is critical. Correct track stress modification is also essential for lowering early wear on undercarriage components.

Final Thought

Finally, undercarriage components are vital parts for heavy tools, playing important duties in keeping stability and functionality. Comprehending the various kinds of track chains, rollers, sprockets, and idlers is essential for proper maintenance and longevity of the tools. By following upkeep ideas and regularly inspecting and replacing used parts, operators can ensure the optimum efficiency and performance of their heavy equipment. Correct treatment and focus to undercarriage components are key to making the most of tools life-span and performance.

The undercarriage is composed of numerous important components such as track chains, track shoes, sprockets, idlers, rollers, and track frames. The track chains and track footwear help in providing grip and support, while the sprockets and idlers assist in driving the tracks efficiently (undercarriage parts). There are primarily two types of track chains utilized in hefty tools: sealed and oiled track chains (SALT) and completely dry track chains. Proper selection and upkeep of track chains are essential to make sure the total efficiency and durability of heavy tools undercarriages

Gears are indispensable parts of heavy tools undercarriages, liable for moving power from the equipment to the track chain.

Comments on “From Sprockets to Idlers: The Full Service for Reliable Undercarriage Parts”